March 2017

Flashing

KICKING OUT THE WATER

Kick-out or diverter flashing is critical in keeping water from entering behind systems with roof intersections.

Kickout flashing, also known as diverter flashing, is a special type of flashing which diverts rainwater away from the cladding. When properly installed, kickout flashing protects the building envelope from water intrusion.

Lack of kickout flashing can lead to a large amount of water behind the cladding and/or into the wall cavity. There are three typical issues with kickout flashing. First, kickout flashing is absent where required.

Second, the kickout is improperly installed. Although flashing is present, proper installation is essential to properly functioning flashing. Deficiencies include: flashing too short, flashing was not constructed properly, flashing is not integrated properly into roofing materials and step flashing, or flashing is not properly sealed.

Third, homeowner improper modification of flashing. To be effective, flashing must be visible. Due to the size required, some homeowners do not like the look of flashing sticking out above the gutters or at other locations. They take it upon themselves to modify and cut back the flashing. This modification can affect the performance of the flashing.

Lack of and/or improper kickout flashing is responsible for a large portion of damage found on homes. Kickout flashing can be retro-fitted into existing installation to correct missing or improper flashing. There are a variety of options available for seamless, prefabricated flashing in a variety of colors.

February 2017

Terminations

TERMINATE...TERMINATE...TERMINATE

Adhered Stone Veneer systems should have proper terminations with weep screed at roof lines and soft/hard grade.

Stone veneer systems typically require water resistive barriers (WRB) for proper installation. These are installed between the substrate and stone veneer system to protect the structure from incidental moisture. The water resistive barriers cannot properly perform if there is nowhere for the water to safely escape. Additionally, if the termination is below grade, the possibility of insects entering the structure is more likely.

Stone veneer is properly terminated above the roof and grade when the water resistive barrier is properly integrated into weep screed and/or termination flashing and the termination is above grades.

Terminations at soft grade (mulch, lawn) can be accomplished in several ways. Typically, stone veneer should be held up 4" above soft grade. The weep screed would be installed 4" or more above soft grade with the foundation exposed below.

Alternatively, when stone veneer is to be installed continuing below grade, the weep screed can be installed at the wall to foundation transition incorporating additional flashing. This additional flashing isolates the lower stone from the stone above.

Unfortunately, many contractors are not installing proper weep flashing. Weep flashing can be retro-fitted into existing stone veneer installations where missing or improperly terminated below grade.

January 2017

Contractors

ARE THEY QUALIFIED?

Selecting a qualified repair contractor is an essential step in bringing your system up to grade.

Far too many contractors repairing stone veneer, stucco and EIFS systems are the same contractors installing the systems improperly.

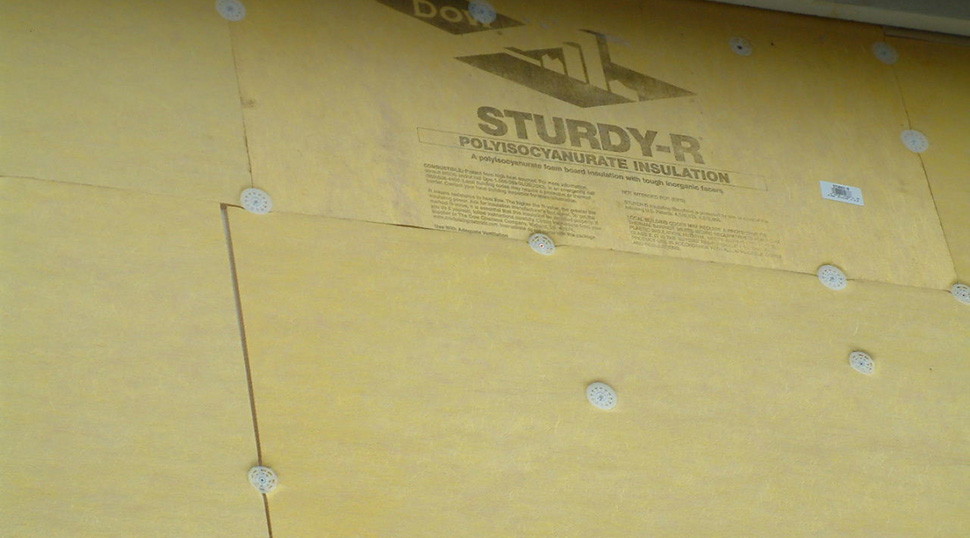

The photo above shows improper attachment of the insulation board over open framing. The contractor used fasteners specified for expanded foam when this extruded foam foam was installed. Additionally, the fastener spacing was inadequate. This occurs due to lack of knowledge and/or training, purposeful use of inadequate materials on hand, or... who knows what is going through some of the contractors heads.

You must perform your due diligence in selecting your contractor. That is true whether it is for initial installation, maintenance (sealant does need to be replaced from time to time) or to perform repairs.

Contractors should be very knowledgeable and experienced in the work they will be performing. There is no one qualification or certification which will show this. It is up to you to access the contractors qualifications. Are they certified by any industry groups/manufacturers? Do they encourage continual training and education of their employees? Do they perform the work themselves or is it sub-contracted out? How long have they been doing this type of work and do they have references? Are they insured? Have you checked for reviews, court cases and other available information available online about the company?

You can never ask too many questions when it concerns who you allow to work on your home.

December 2016

Inspections

3RD-PARTY, YOUR FIRST CHOICE

Having an independent evaluation of the building envelope can provide needed reassurance and guidance.

Ask a builder if there is anything wrong with the installation and they may tell you "no". Their stucco sub-contractor told them the installation is correct and they have been doing it like that for 30 years.

Ask the home owner if there have been any issues with the stucco and they may tell you they haven't noticed anything.

Can you rely on these statements? I wouldn't without verification. The builder may genuinely believe the stucco is installed properly because that's what his stucco contractor told him. He has stucco installed on many of the homes he builds but has basic knowledge of the system. The stucco contractor installed the system and either thinks they performed the installation properly or knows they didn't and does not want to address the additional cost of possible repairs. Even if the stucco contractor intended to install the system correctly, one of his employees could have omitted a critical detail.

Without a knowledgeable, independent inspector reviewing the system for installation deficiencies and moisture intrusion, you may not get a true opinion which you can rely on.

November 2016

Windows

WINDOWS, VIEWING THE ISSUES

Light is the only thing you want going through your window, not water.

The photo above shows moisture intrusion below a window in an EIFS clad home.

There are numerous ways moisture can enter behind your cladding. The window perimeter should be properly sealed with the appropriate joint detail and sealant installed. Often, contractors will butt the cladding tight against the window without sealant.

Windows should contain proper flashing. This includes head and sill flashing where required. The purpose of the flashing is to direct moisture away from the window and/or system. When flashing is not present, moisture can more easily enter behind the cladding. Additionally, far too often, flashing lacks proper installation. Flashing installation should contain end-dams where required. End-dams stop the water from flowing off the side of the flashing and directs it outward.

Windows can leak within their construction. It is important to determine if the window is leaking itself. IF there is a window leak within the construction, the construction can be sealed and/or sill flashing can be retrofitted if not present.

October 2016

Repairs

TO MONITOR, OR NOT TO MONITOR

...that is the question. Repairs will not help if not performed properly. Don't pay for repairs more than once.

The photo above shows what was found on a follow-up inspection after repairs were completed.

The original inspection indicated kickout flashing was absent and needed to be installed, along with several other deficiencies identified. No monitoring of the repairs were performed.

Once the repair contractor notified the homeowner the repairs were completed, a repair follow-up inspection was performed. During the inspection, it was observed the repair contractor improperly installed multiple kickout flashings. In an attempt to conceal the fact the flashing was not properly installed behind the EIFS and integrated into the roof and step-flashing, the repair contractor simply cut the flashing where it would have been protruding from the EIFS, if installed correctly, and placed the edges into sealant. Since the kickout flashings are sealed after installation, I believe they thought it wouldn't be caught.

Not only was this improper, the homeowner most likely paid for what they thought was a proper repair. Cutting flashing and sealing to the surface verses cutting open the EIFS, integrating the kickout flashing into the EIFS, roof and step-flashing are quite different in regards to time and materials involved.

Now this was caught since some of the work was exposed. However, many of the repairs needed and process involved are hidden from the inspector once they have been completed. If you want the most assurance the repairs are completed properly, it is recommended the repairs be monitored.

The information provided above is the opinion of Litcon Consulting. Litcon Consulting does not guarantee the accuracy, completeness or suitability for a specific purpose. Each structure, installation, contractor is unique and should be dealt with individually.